OEM&ODM Service

We sincerely and safely provide you with full-process support from planning consultation, design and development to production and sales.

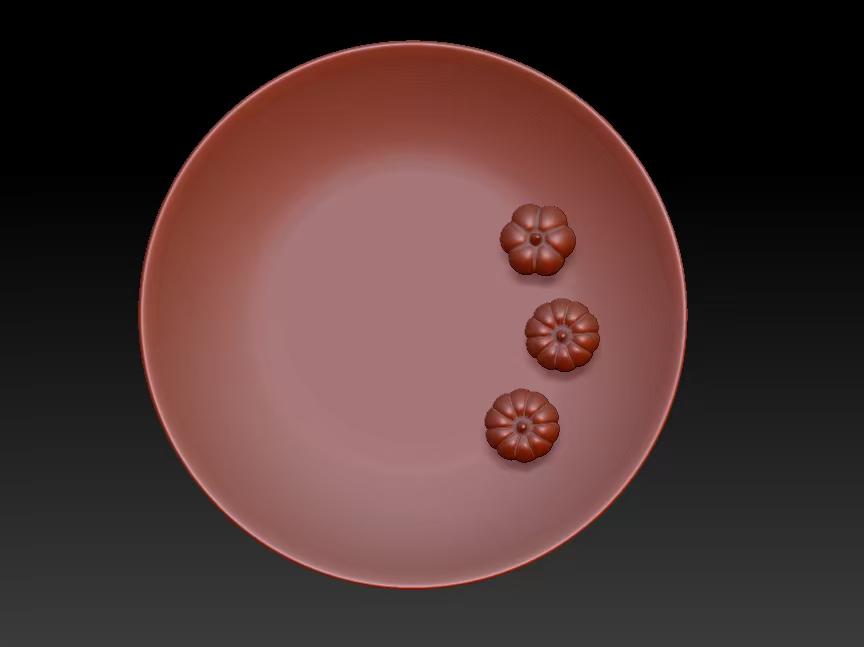

3D Modeling/Hand-Sculpting

Artificial sculpture or 3D modeling is performed according to the difficulty and restoration requirements of product design. Currently, 3D modeling is widely used, and the restoration degree reaches 100%.

- 3D modeling or handcrafted sculpture for customer confirmation

- 3D printed plastic model

- Make gypsum molds with plastic models

Production of Gypsum Molds

Mold makers make plaster molds based on sculptures or 3D plastic models.

Grouting · Trimming · Forming

After the mold is completed, grouting and shaping are carried out. The clay body needs to undergo a series of product improvement operations such as water wiping and shaping until there are no impurities in the product before it can be fired into a clay body next time.

- Ceramic Grouting

- Clay Body Shaping

- Manual water wiping and shaping of the clay body

Ceramic·Glazing·Painting·Decal

After the ceramic body is fired, workers start to carry out manual painting and decal application and other manual production.

- Artificial painting

- Glazing pottery

- Decal paper for ceramic ware

Fired in a kiln

After the glazing, painting and decal application processes are completed, the products are sent into the kiln in batches for firing.

Selection of porcelain and quality inspection

After the finished products are fired, workers will conduct inspections and select the porcelain. They will pick out the substandard products (such as pinholes, dirty color, uneven glaze, and mottled patterns, etc.) and transport the qualified products to the packaging area.

Product packaging·Container loading

All products that have passed quality inspection are shipped to the packaging workshop and packaged by workers.

Stay Updated with Our Latest Innovations

Subscribe to our newsletter and be the first to know about new products, industry insights, and exclusive offers.